Robots seem to be taking control of the industries of the future, and the screwing area is no exception. Although it is a process that may seem very simple, it is a vital process when it comes to fixing any response, electronic card or compound to each other.

Said procedure entails the fact of hiring specialized personnel in the area, who will be in charge of classifying the material destined for the procedure, ordering it, and then carrying out the screwing process. Although this technique may seem economical at first, in the long run, the use of a lot of personnel in an area, it becomes a liability for the company: It dramatically increases production costs.

Therefore, several industries have sought solutions for the management of this basic process, and the future lies in the use of robots to replace personnel: A production line for counting, sorting, screwing and constant fixing.

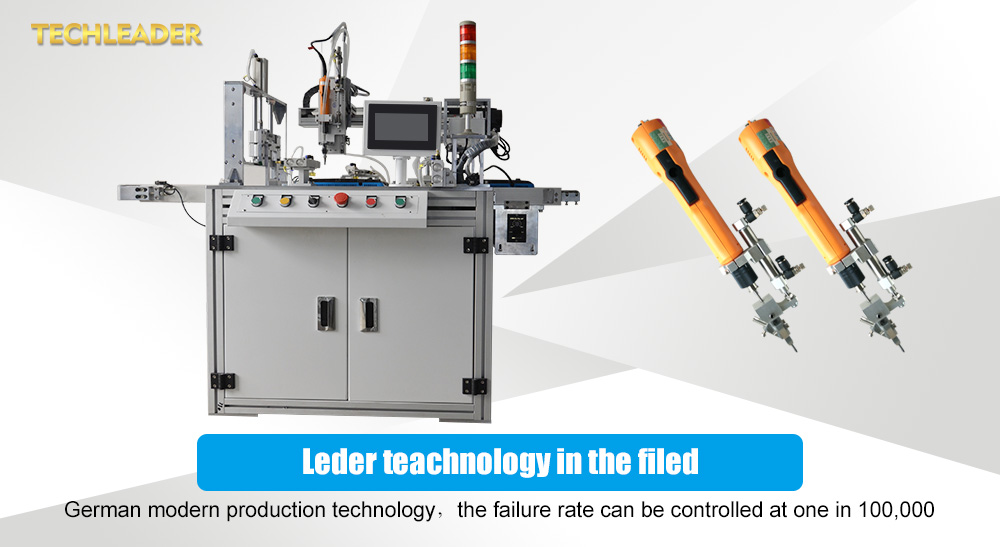

automatic screw tightening machine

What is automatic screw feeder machine?

Automatic screw feeder machine is an assembly equipment manufactured for the task of supplying screws and screws in the field of automation, assembly of components, electronic circuit boards, machinery, smart phones, electricity Wireless phones, computers, navigation screens, sound boxes, cameras, small devices, toys … The machine has the function of quickly and accurately aligning screws. The machine can be used to classify and supply screws for assembly for different types of screw heads …and so on.

Automatic screw feeder machine function

This machine is the first but not least of the production line. The automatic screw feeder machine is initially responsible for counting the screws provided for each function. In this way, the quantity of raw material (screws) used in each base plate is assured, and no material is wasted in any way.

In addition to counting, the machine has the ability to receive the screws and gradually place them in a row to be used on the production line. This machine can be graduated to determine the speed of screw delivery.

By using said machine, the loss of raw material in screws is greatly reduced. The machine supplies exactly those that will be used for each plate and keeps a count of them. In this way, there is material to continue with the work.

In addition, it greatly facilitates the work of the automatic screw locking machine, which will only have to remove the screw from the production line by means of a magnetized tip and will be ready to screw.

Function of the automatic screw locking machine in the automatic production line

This is the final part of the assembly machine. Being a robot, it has a screwdriver with a magnetized tip, which will allow you to remove the screw from the automatic screw feeder machine and through a previously given programming, it will seek to place it in the exact positions that were given and with the pressure level suitable.

This part supplies the necessary personnel for screwing. The staff will only seek to place the plates to be screwed and the machine will keep its work constant while placing and removing plates. With this, you have a fully automated production system, aimed at increasing production in large quantities. In addition, taking into account that it is an investment in a strong asset, it ends up being an investment in not so long term.

Studies indicate that the return on investment is from 6 months to 1 year, and then the machine will be maintained with much longer life. A true marvel for technology in the bolting area.

For more about automatic screw feeder machine,you can pay a visit to https://www.automatedfl.com