Impact Of Automatic Screw Feeders System Upon Manufacturing Fully Automated Assembly Line

Introduction

The production houses or production factories are responsible for all the goods and products they produce in their unit. For this purpose, getting suitable automatic screw feeders installed in the production house is essential. This is an impactful decision. The impact, either good or bad, can cause severe outcomes at the production rate of your business. As compared to any other production methods, automatic screw feeding processing has numerous benefits upon the production. But, it does not mean that it can never cause damages.

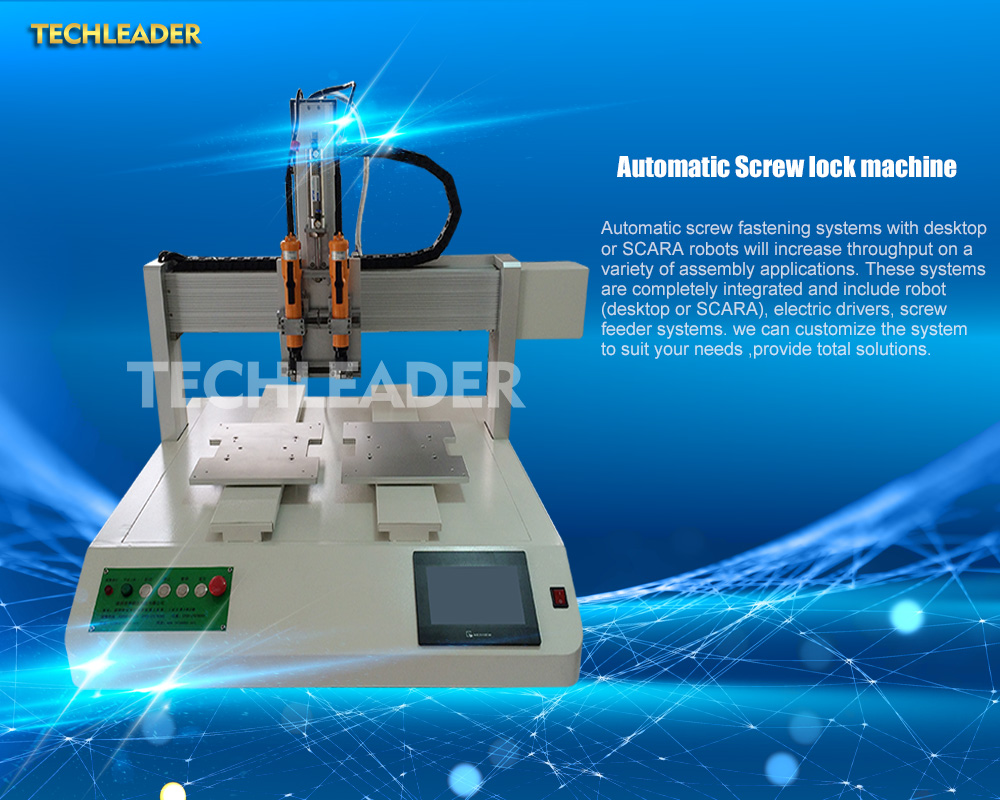

automatic screw feeding screwdriver inline screwdriver

Positive Impact of Automatic Screw Feeding

Every production house or factory has its requirement of machinery. It depends upon the need of the business to have which sort of machine or human labor. But, installing automatic screw feeders can help you in many ways. A few of them are discussed below.

• Speedy Production

Use automatic machines can increase the speed of the production process. When we take human labor, it takes a lot of time to adjust, learn, and practice the process. Human labor gets tired too soon and needs more breaks than automatic screw feeding machines.

The work done by human labor is double-checked and then passed to the client. Hence, it takes more time, and it will affect the overall revenue generation as well. Moreover, it takes real-time to search for the right screw fit and then fix it as well.

Automatic screw feeders can do all of this in relatively less time with minimum effort. A robotic arm finds itself the right fit and fixes it over. It fixes almost 70 pieces per minute.

• Proficiency

All the automatic screw driving system manufacturers focus on the proficiency of their devices. They make supremely proficient automatic screw feeders that help the production process be done in less time and increase the revenue with enlarged product demand.

Human labor works slower, and it is difficult to take too much time for order completion. The workers need to be more trained and speedy to help the production keep going. A minor mistake can cause severe damages to the entire unit. These automatic screw feeding machines work more genuinely and accurately. There are fewer chances of error as well. The automatic screw feeders are a well-prepared and high-tech device that works with precision and proficiency.

• Time Saver

All the automated screw driving system manufacturers have made a time saver machine in an automatic screw feeder. This tool can do wonders in less time and generate excellent results. Human labor cannot work at that much speed, so it takes more time. But, these automatic machines have a speedy working capacity. These automatic screw feeders have a robotic arm that fixes more screws in less time than human hands.

A regular automatic machine can fix a minimum of 70 pieces screws per minute. But, human hands cannot do. So, it saves a lot of time. If production will be done less time than, more orders can be taken to consume enough time and increase revenues.

• Increased Production and Revenue

The automatic screw feeders work more proficiently in less time with enough speed. All these factors help all the production factories get more and more orders and generate increased revenues. Furthermore, all the goods manufactured with automatic screw feeding devices are more accurate technologically.

The screws are fixed and fastened with robotic arms so, these are more work efficient. The projects with large assembling requirements can be affected by time, speed, and proficiency. The production orders completed within time will result in an effective and long-term relationship with the client. Hence, the production will be increased as you will bet on more projects that will generate more revenues.

• Production Cost

Working with automatic screw feeders can decrease your production cost as well. Human labor is slower, and it takes more time to assemble and manufacture. So, you will hire more labor to get more work done in less time. This will cost you a little more. If you buy automatic screw feeders once, it will be a long-term investment for the production house. Instead of hiring more human labor, an automatic screw feeder will be the more smart option. One machine will serve the job of more than ten people. Hence, the cost of the wages paid for those people will be reduced, and overall production costs will be reduced.

• Easy to Operate

All the automatic screw feeders are very easy to operate and use. The automatic screw feeder system is acceptable by any production house depending upon its requirements. These systems do not have a high-tech operating system that is leaned through any course. Any regular operator can learn to figure it out quickly.

Negative Impact of Automatic Screw Feeders

Automatic screw feeders are pretty helpful, and they have more positive impacts on production. But there is one negative impact that these automatic screw feeders have taken the place of human laborers. Hence, the ratio of unemployment is increased. Many workers are down-sized, and these machines are preferred as they work slower than these electronic robotic machines. Human workers are less proficient as well.

All the human workers take more time to adjust, select the right screw and fasten them. But, the machines do it themselves and help to reduce the time of production as well. Hence, these automatic screw feeders have a negative impact as well. Yes, it is irrelevant to production but, it is a bitter fact.

Automatic Screw Feeders System Manufacturers in china

Final Verdict

Everything has some positive or negative impact. Automatic screw feeders are more helpful, and they contain more impactful results as well. So, installing an automatic screw feeder would be an excellent decision to expand and improvise the production process. The improved production and more work projects will help you generate more revenues and profits.