How To Select The Right Automatic Screw Feeding System For Manufacturing Fully Automated Assembly Line?

Are you planning to buy or add on an automatic screw feeder system? Else being the production manager, you might have complete knowledge about the significance of the manufacturing process. It is not just enough to produce top-notch and high premium products for excelling and ruling the markets. Instead, it is also crucial to design an effective and efficient process for the manufacturing of goods. Undoubtedly, the customer only notices the end product and is only concern about it. The company will only determine its success not only through customers and its satisfaction. It is a compulsion on it to look in its financial aspects too. Every manufacturer has to consider producing its top-notch products within its profit margin.

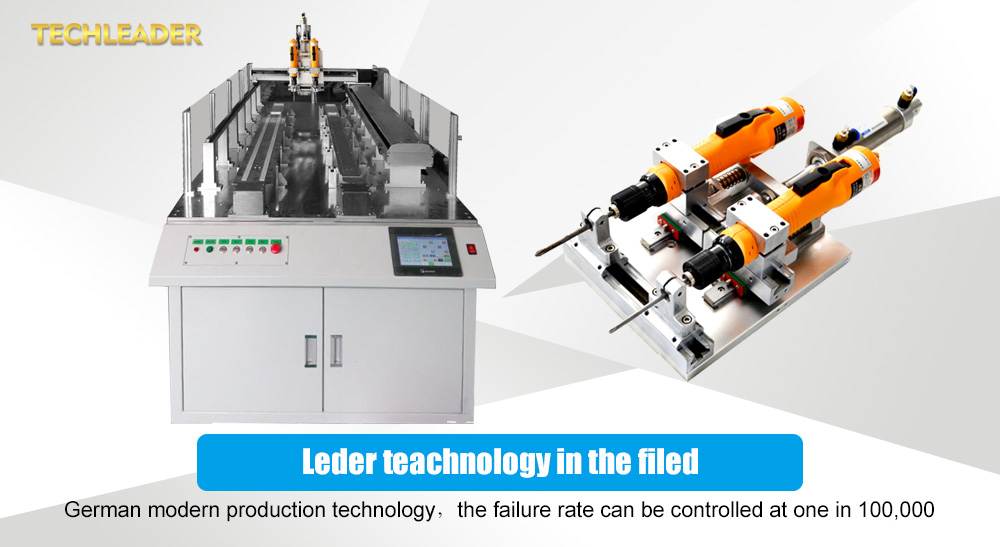

automatic feed screwdriver system manufacturer

The health of your profit ratios is highly dependent on the efficiency of the entire manufacturing procedure. Thus, it turns equally valuable and worthy for the third parties to produce items for the companies, just like how businesses manufacture in-house goods. It is crucial to remember that whether you produce for the consumers directly or the other companies, efficient production will be the key to success. You are likely to increase profit margins and complete more orders.

Therefore, the manufacturer must develop an efficient production system for achieving success. As you know, most business operations have their workings and operations with fasteners and screws, so it is a must to choose an automatic screw feeder system. It will be an ideal step for assuring to meet the production quotas at the right time and every time. Thus, it is better to look in for the best Automatic Screw Feeder Machine Manufacturer for determining the perfect and excellent assembly automation screw feeders.

Factors to consider for the best assembly automation screw feeders:

It is a must to look at the factors before buying the best and most suitable automation screwdriver for yourself. Being a layman, indeed, we will look for the material, requirements, and design of the product. But there is something more in it.

Before choosing the automatic screw feeder system, you have to consider the needs and requirements of your manufacturing procedure. Just look in for the fundamental factors to decide what you want for your manufacturing department? For instance: What should be the size of your screws? Should you opt for a human operator or automatic screw feeder system? What will be your repairs and maintenance plan?

When such a question is popping in your mind, you must consider the four most important factors for selecting the automatic screw feeder system:

Screw size

Most automatic screw feeder systems can’t supply all sizes of the screws that are available in the markets. You will notice the automatic screw feeder system’s general trend with a particular size of screws, ranging from micro, small, or large screws. You will need a micro-size screw for the production of internal medical units or consumer electronics. Moreover, you will need small screws for the manufacturing of packaging applications or aviation components. Moreover, screw feeders will need large-sized screws for defense and automotive goods.

Screw coating

Some screws are more delicate and tend to break. It is possible that the coating of some types may be so sensitive and can easily be destroyed or crunched due to the passage of an automatic screw feeder system. For instance, you may come across screws made up of other than alloys and steel, being lightweight and made up of plastic, they can easily deform, break, destroy, or bent. Make sure to choose the automatic screw feeder system, which can handle carefully considering the kinds of screws used in your manufacturing procedures.

Automation level

Whether it is the operation of minor line assembly or single cell, these both operations will require different screws for feeding needs than the whole assembly automation screw feeders. However, due to financial constraints, it may be hard for the minor line assembly to choose for becoming fully automatic and investing hefty amounts in high volume and high-speed automatic screw feeder system. However, suppose the automatic feed screwdriver system manufacturer does not work on other capacities to make its manufacturing process cost-effective. In that case, all other measures like the massive investment in an automatic screw feeder system will not be more than a waste. The costs will be far way more and beyond than the returns. Contradictory, the large manufacturers may find the compulsion to choose an extensive automatic feed screwdriver system to minimize their cost and improve their efficiency in terms of output and waste. Their margins should not drop below the sustainable levels. Therefore, it is vital to choose an automatic feed screwdriver system by realistically evaluating your needs. After that, choose whether a fully automatic or semi-automatic feed screwdriver system depending on your ROI.

Supplier’s location

It is essential to pay particular consideration to the aspect of repair and maintenance for the assembly operations. Definitely, the whole manufacturing process relies on the automatic feed screwdriver system to stay tuned up and in running condition. Unluckily, if your feeding system goes down, it will adversely affect production. The location of the supplier will indeed matter a lot when you have to rely on the automatic feed screwdriver system manufacturer’s technicians. It is better to opt for your nearby suppliers to help you with the unplanned shutdown in a better and more rapid manner. Ultimately, you will be able to cut down idle hours and increase your production.

China automatic feed screwdriver system manufacturer

Final verdict

It is better to opt for an automatic feed screwdriver system manufacturer for nearby services and avoiding any hassle and mess in the production process. It will help if you consider the above factors for checking the financial feasibility of the investment of an automatic feed screwdriver system. It is necessary to watch out for your needs and requirements to buy the best automatic feed screwdriver system and enjoy quality products with high margins. Watch out for both long-term and short-term goals.