Comparing Automatic Screw Drivers with Manual Options

Almost every manufactured product has screws in it. Whether it is cell phone hardware, household appliances, medical devices, or aerospace machinery, screws of every shape and size can be found. Putting in those screws requires the use of screwdrivers.

With different types and sizes of screws, the requirements for screwdrivers also change. There are various options available for screwdrivers. These drivers are selected on the basis of work requirements and screw specifications.

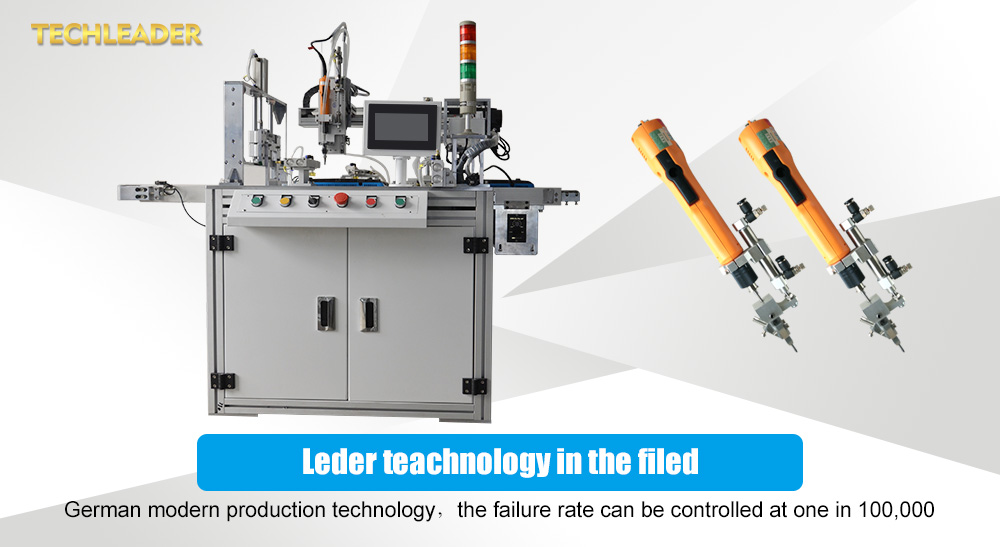

automatic screw tightening machine

Manual or Electric

For screwdrivers, the first decision to make is whether you need a manual or an electric screwdriver. It is dependent on how frequently that screwdriver is needed for tightening screws. It is good to have a manual driver at home just in case you have to use it. But if there is a frequent need for locking and unlocking screws, then an electric screwdriver is a better choice. It is efficient and saves time by the hours over constant use.

Anyone can use a manual screwdriver, but an electric driver requires some getting used to operating it. It is generally preferred by professionals such as electricians, carpenters, etc. But some automatic screw feeder machine manufacturers also incorporate screwdrivers to offer efficiency and precision for manufacturing and production plants.

Putting in several screws per day using a manual screwdriver is simply inefficient and tiring. It is quite hectic to [pick each screw by hand and place it in its hole, then use a driver to lock it in place and then check it to see if it is locked all the way. Instead, it would be a lot easier to simply place a screw and press the driver gently to lock it in place perfectly. There is no need to twist or worrying about poorly locked screws. The automatic feed screwdriver system manufacturers have provided a viable solution for having to pick and place a screw every time. These automatic feeders supply screws constantly that are lock using the electric screwdrivers in less than a second. These electric screwdrivers along with automatic screw feeder machines have made the assembly quite an easy task and a highly efficient one.

Cord or Cordless

Electric screwdrivers have a definite leg up over the manual ones. But for electric screwdrivers, the choice for cord and cordless ones is available. Both are valid options. The cordless drivers use AC current and need a constant supply of electricity to work. However, they offer excellent work efficiency as compared to cordless ones. They operate on batteries that need to be changed periodically. Also, you have to take the batteries out before putting the device in storage after fining the task. Otherwise, the batteries will drain too quickly and it will become a costly venture. The battery-operated driver is not feasible for long hours and on the other hand, there isn’t always an easily accessible outlet available.

The cordless driver can sever for limited usage, but the electric drivers with cords can be configured for small and large-scale usage with certain modifications readily provided by automated screw driving system manufacturers.

Torque or Lighting

An additional feature for electric screwdrivers is the torque. It plays an important role in deciding the strength and speed required for tightening a particular screw. As the torque of the screwdriver increases, it becomes easier to lock screws with harder materials. The toque gets better with the speed of the screwdriver that depends on the AC current or the voltage of the battery-operated drivers.

Why Automated Screwdrivers are Better

It is better to use automated screwdrivers and feeders to gain excellent work efficiency and high accuracy. Also, it involves less labor and needs minimal human supervision to operate. They are much more versatile than the manual option which gets the job done but takes 4x more time to finish a job and with less accuracy. This is why professionals, small and large-scale production houses, and assembly lines prefer automated screw driving systems.

Here are some major benefits of these automated screwdrivers:

• Comfortable to Work With

The automated screw driving system manufacturers have engineered these devices to be very easy to grip and use for extended periods. They can be held in hand, fixed, moveable, fixed using spring attachment over the head, etc. There are many versions and any one of them can be used according to the requirements of the task at hand. The controls on the handheld drives work with a gentle touch. Similarly, the screws can be locked using the gentle press instead of putting pressure on the driver to keep the screw in place and then twist it several times. In short, the fully automated screwdrivers are much easier to work with especially with automated screw feeders.

• Can be Configured into Assembly Lines

Automatic screw feeder machine manufacturers can configure screw feeders and screwdrivers to work in an assembly line. They can be configured as fixed devices as desktop machines or the moveable ones for a robotic arm. The fixed and moveable feeders and drivers are generally used for single-unit production but can be easily reprogrammed to work on other items too. This makes them a one-time investment which is an ideal feature.

• Various Options for Usability Requirements

There are various options provided by automated screw driving system manufacturers. Some of these options are electric-powered torque drivers, magnetic feed drivers, suction screwdrivers, pneumatic screwdrivers, etc. They are all incredibly useful in their own distinct way. Using any type also depends on the preferences of the user or operator as well as the production or assembly plant requirement. But in any case, the combo devices for screw feeders and drivers are simply perfect for simultaneously supplying and lock the screws. This practice saves time, effort, and labor costs while delivering high precision and accuracy of output.

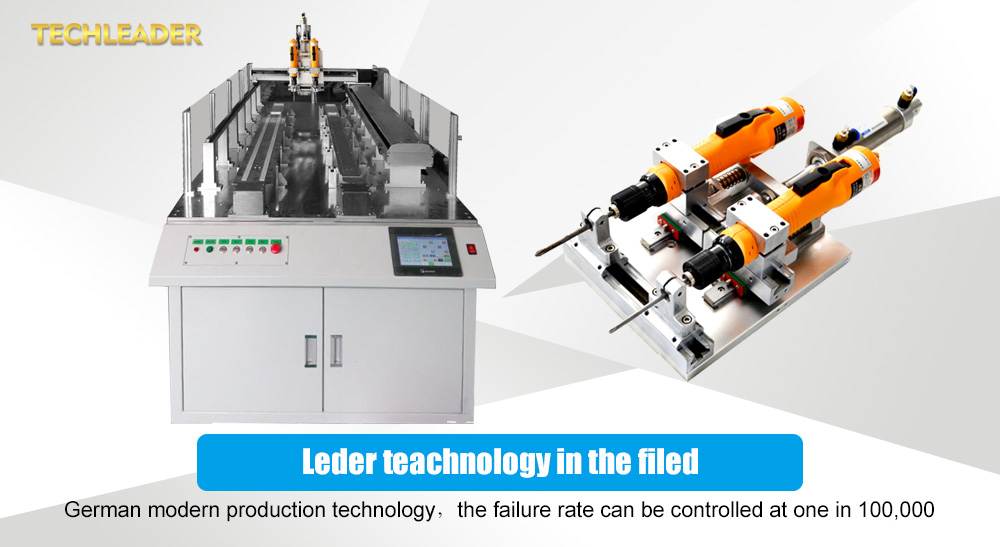

automatic feed screwdriver system manufacturer

From manual screwdriver to the fully automated version provided by automated screw driving system manufacturers, there are various options available. The automatic feed screwdriver system manufacturers have a wide selection of automated drivers, screw feeders, and combos of both automated drivers and feeders. So, these devices can be obtained for personal use as well as for large-scale assembly automation.