A comprehensive guide to the automatic screw feeder machine.

Due to advancements in technology, numerous machines and devices are produced to make our lives a lot easier. For example, the feeding and locking of screws when done manually can become very tiring for the operators. This then affects the manufacturer in the part of inefficiency.

When we make use of manual labour in our processes, this results in a compromise in capacity and efficiency. To help solve this problem, the automatic screw feeder machine was developed. This machine can be used in working areas and shops.

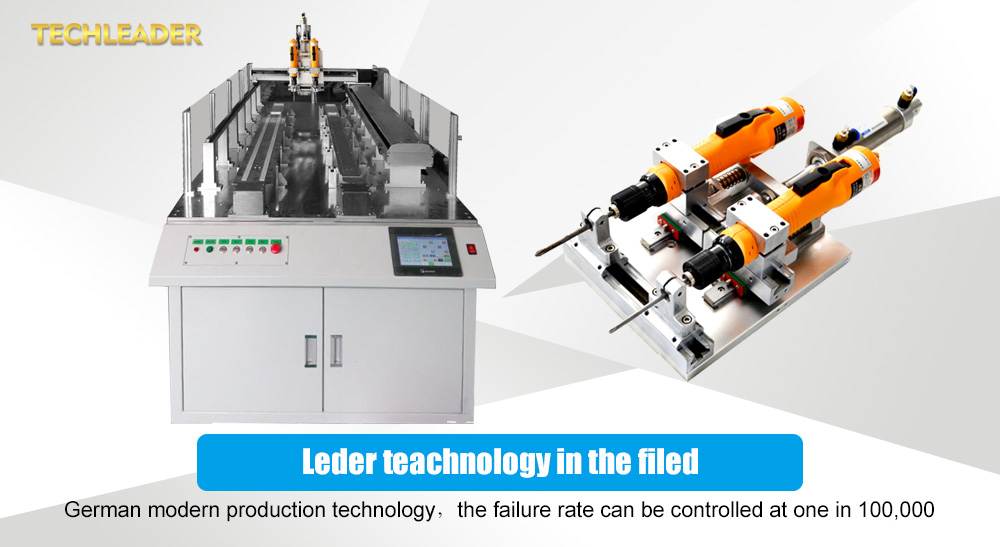

china automatic screw feeder machine manufacturers

What is the meaning of the automatic Screwdriver Feeder?

The automatic screwdriver feeder is a handy automatic machine that is equipped with an automatic mechanism that is used to complete several important tasks such as receiving screws, placing screws, and screw locking. This screw machine comes with two different parts;

• The Feeder Device: This is the part that is used for selecting the screws and fixing the screws.

• The Electric Screwdriver device: This is the part that is used to receive and tighten up the screws.

This automatic screw feeder machine manufacturer works to produce these tools to help increase the efficiency of workers while also reducing labour costs. Technically, there are two types of screw feeder drivers, which are:

1). The Handheld Automatic Screw Feeder Driver

The handheld automatic screw feeder driver is a lightweight and small device that makes machine handling a lot easier. To operate this device, you will point the screwdriver device to the screw hole. You will then lock up the screw.

One good thing about this is that you will not need to wait before you put the screw in the next hole. This is done automatically by the screw feeder as it transfers a new screw to the driver soon as you lock one in. These assembly automation screw feeders are primarily used in production assembly lines for the production of a wide range of devices like toys, electronics, mechanical devices, household appliances, and so on.

2). The Fully Automatic Screw Feeder System

The fully automatic screw feeder driver system is used to eliminate the amount of human labour needed in the handheld automatic screw feeder. This fully automatic screw feeder system consists of different components like the screwdriver that is fixed to the robotic and automatic control. It also consists of the multi-axis workbench that is used to perform operations in the assembly line automatically. Other parts of the functions work in the same way as the handheld screw feeder.

Knowing what assembly automatic screw feeders you need for your product.

It is the intention of the automatic feed screwdriver system manufacturer that their products will meet the demands of their clients. If you are looking to install the automatic screw feeder system in your product line, there are several factors that you need to take into consideration. You will need to check whether the system will be beneficial to your product assembly line.

Assembly automation screw feeders produce large amounts of similar screws at a fast pace to a given location. What if the product you produce needs only just three screws which all come in various sizes. This means that you will have to produce three different automatic screw systems, which will result in lots of costs. This will not offer many benefits to the speed of your production line.

On the other hand, it might be that the product could need between thirty and forty similar screws. This means that you need just one screw feeder system that can do the work in a short time.

Calculating the benefits

The total benefits from the screw presenter can be calculated from your automatic screw feeder machine manufacturer with the equation;

The Total Benefit = (Number of screws needed) x (Total time savings with one screw)

Probably, this automatic screw feeder system will pay back the cost that was initially invested in it within a short time. It might also be able to generate the returns that are expected on it. If this is right in your case, then it means that this automatic screw feeder system is the right alternative that your company needs.

Setting the screw feeders in the proper position

Apart from ensuring that you get the right screw feeders for your product: you are also expected to put it in its proper position. The following points will need to be considered when you are trying to select your screw feeder’s position in the production line:

• It should work smoothly with your production assembly process.

• The operator will have to comfortably and ergonomically reach it.

• You will need to quickly refill it and put it in decent working order.

It is important that you locate the screw presenter, and put the workstation of the operator in the right position. This applies whether you are in the cell, hybrid, or line manufacturing phase.

Generally, the safest thing to do here is to position the workstation very close to the next and final assembly stations of your product. This is used to make sure that the products move down the line in a quick way that is possible.

It is important to directly look for the screw feeder since declines in the general quality of assembly flow can counteract any increases in the performance of the operator that has been effected by this screw feeder.

Smart ways to refill

Simultaneously, designing the mechanism for the screw dispenser to enable easy refilling is an excellent idea. Screw feeders can be fed primarily in two different manners: this could be through central piping or with the use of an input bin.

Large input bins with local screw feeders help eliminate the need to use regular refills. During the planning of the location of the device for the screw presenter, you need to ensure accessibility wherever necessary.

automatic feed screwdriver system manufacturer

Things to consider if you are making use of human labour

Finally, for people making use of human assembly labour, it is important to put the screwdriver by considering ergonomics. The wrong assembly conditions can lead to repetitive motion problems, this results in job downtime as well as treatment expenses.

You will need to put the screw feeder system in a place that will encourage the comfortability of the operator. This includes a systematic design to enhance spinning, picking up, and fastening of screws to prevent injuries from repetitive motions.

The automatic screw feeders will enhance the efficiency of the production lines by making them about 50% faster. But, to understand the benefits of this productivity, you will need to carefully plan out the operation of the screw supply. For you to make the most in terms of money spent on investment for the automatic screw feeder, you will need to consider its position and application.