Screwing delicate material and the use of automatic screw fastening machines

Automatic feed screwdriver systems are a worthy addition to many company processes. They can be designed in a way that they handle very specific tasks. Manual installation of screws is not always the best because of the possible errors that could arise. Also, mistakes are more likely to occur with manual installations. Humans are quite likely to cause wastages and damages compared to machines, and that is why machines are a preference in most cases.

One of the things that make the auto screw feeding machines suitable for use is the ease at which they can screw delicate material without damaging it. They use the right pressure, which does not damage the components or devices regardless of how delicate they are. This is possible when the machines are pre-programmed for specific use in a particular industry.

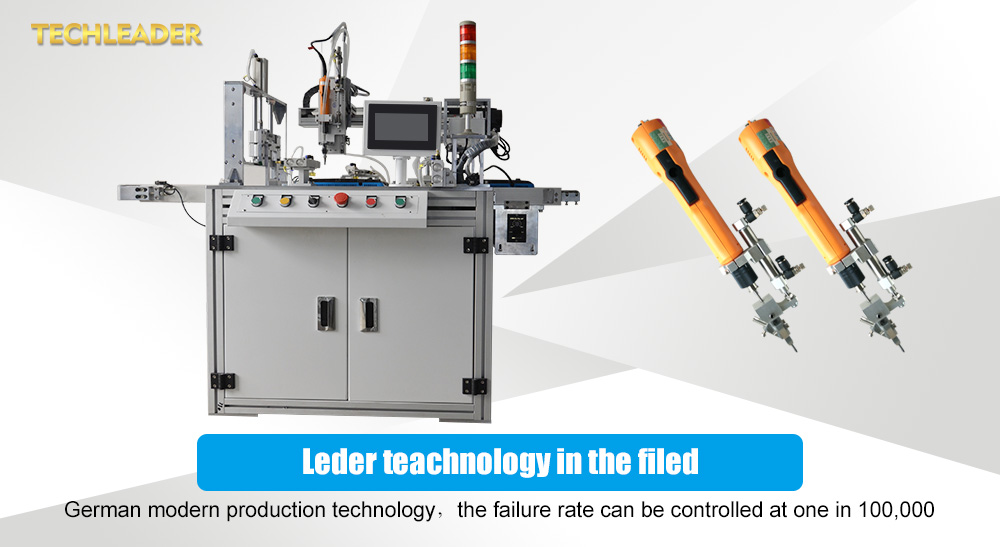

automatic screw tightening machine

Most automatic feed screwdriver systems use an infallible programming kind of system. The machine knows exactly where holes have to be made through the programming, and it is programmed to handle that. When all is set, the machine can easily perform the said procedures with very little chance of failure. This means that the electronic compounds are not destroyed by drilling. Screwing is only done in the prescribed way, which maintains the product structure to the maximum.

The best automatic screw feeding machines come with pressure programming systems as well. This is due to how susceptible weak materials yield under pressure, especially when screws are too tight or when screws move when they are not fixed right. It’s possible to test the machine on a few components first before proceeding with the entire production. This determines if the programmed pressure is the right amount.

With the programming, the machine is told exactly how much pressure to exert during the screwing process. This makes it possible for the pieces to be fixed strongly but reduces the chances of breaking.

In production, pressure and precision are very important, and these are things easily attainable when the right assembly automation feeders are used. The position of the screw is also as important. The machine needs to screw in the correct position. Failure to do this may cause damage to the entire device or component.

If screwing was to be done using the regular screwdriver, the screw will likely be crooked. While this may not seem like a serious thing at first, it can cause great issues and compromise the device’s integrity. When a screw is twisted, there is no way it can fit the device as required. There are many risks involved when tightening is done with very little pressure. A crooked screw could also cause breakages to the material. Such a default may also cause the screw to be too tight and impossible to remove when the need arises.

automatic screw locking machine

The assembly automation screw feeders are uniquely created. This means that pieces that are used for the screwing process are covered using clamps that hold them. In most cases, the clamp has a flat head. The clamp’s head is placed on the material, and it is this that turns the device. This makes the machine place the screw in a perfect position reducing the chances of damage.