Maintaining automatic feed screwdriver systems in your automation manufacturing assembly line

Automatic screw feeding machines have become very common in almost all digital businesses today. These machines make things so much easier. When these machines are at hand, it is important to ensure they are well maintained at all times. There are some tips that can assist in the maintenance of the automatic screw tightening machines. With proper maintenance, the life of these units can be extended to great limits. Taking time to understand the requirements of each system can give a lot of insight into what needs to be done for the best outcomes at all times.

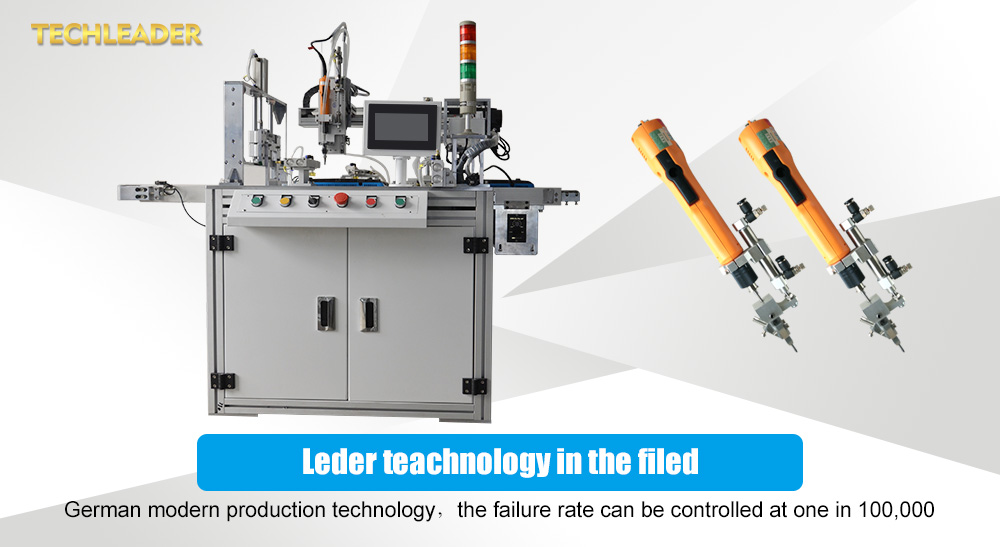

automatic screw tightening machine

1. Finding vibration sources

Being aware of what happens with the machine is one of the most important things you ought to think about. It is important to remain keen with how the machine works. If any changes are witnessed, inspections should be done to avert bigger issues from arising. Most of the automatic feed screwdriver systems are made to be durable and very efficient. However, this does not mean they cannot break down. If there are any vibrations or noise detected from the machine, the best thing is to disconnect the power and inspect it from different angles. In many cases, this can help in identifying the root cause of the issue.

2. Switch the machine off

There are times when the machine is not in use. If this is the case, make sure it is turned off the right way. This saves power and extends the life of the machine; this also helps avoid any clutter after the machine has been used.

3. Unloading

There are instances when production needs to stop for some time for one reason or the other; in such a case, the automatic screw feeding systems should be shielded. It is important to unload the machine entirely and make sure all the areas are wiped and shield as they should be. This maintains the machine well up to the time it needs to be used once again. Special precautions need to be taken when the machine is used to keep it and the operator safe.

4. Cleaning

Most automatic feed screwdriver system manufacturers deliver the machine with some clear instructions regarding maintenance and cleaning of the machine. Cleaning is always an essential part of the machines. This ensures that they remain dust and dirt-free. If cleaning is not done the right way, it does not give the optimum performance. Not cleaning could cause some damages at some point. Most automatic screw feeder machine manufacturers make maintenance services available in different parts of the world. This is an important consideration that has to be made when the initial purchase is being conducted. It helps determine whether the device parts and maintenance services are available where the machine will be operating. This means less downtime and losses should the machine run into issues.

china automatic screw feeder machine manufacturers

5. Lubrication

This is an important part of maintenance. In such a case, it helps to follow the manufacturer’s instructions about the automatic screw tightening machine. Lubrication can help in extending its life. There may also be parts that require regular tightening, as they are prone to becoming loose. However, regular maintenance can help diagnose such issues and get things done the right way.