ロボットスクリューフィーダーシステムを備えた自動スクリューフィーダーマシンとその用途 2021

の 2021, さまざまな用途での中国の自動スクリューフィーダーマシンの必要性

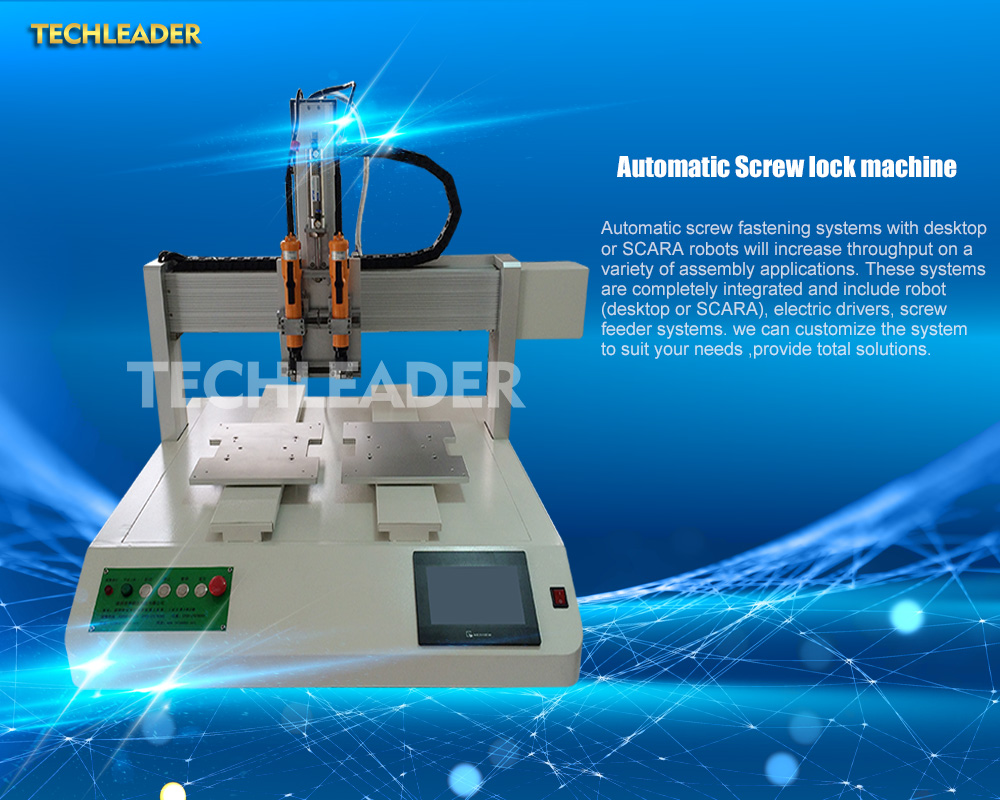

設定された目標に従って物事が確実に流れ、あらゆるタイムラインを満たすために、最高の自動スクリューフィードドライバーシステムを提供するために、最高の自動組立ラインの作成に集中しているメーカーがあります。. 製造と組み立てに関する限り、物事を正しい方法で行うことは依然として重要です. プロセスを自動化するために適切なマシンを粉砕すると、生産とROIに大きな違いが生じる可能性があります.

Anyone in the manufacturing industry and doing things on a large scale needs to integrate an 自動送りドライバーシステム to take care of different things. These are machines that are very beneficial in manufacturing and assembly and should not be taken lightly. The automatic screw fastening machines are designed in such a way that they can handle the installation of so many screws within a very short time.

自動スクリュー送りドライバーインラインドライバー

Automatic screw feeder machines are beneficial to businesses in 2021 in many ways. One of them is a reduced error rate. Machines are not like humans. The automatic screw tightening machines are designed to reduce the margin of error. With the machines, the detection of faults is so much easier. The machines are designed in a way that they can detect when screws have not been fastened the correct way. They can also tell when a screw is missing and give a report on the same.

With the assembly automation screw feeders, it is possible to enjoy better efficiency and output. Better efficiency also means that the machines don’t break down easily and lose production time.

With the automatic screwdriver systems, any company needs far fewer employees at the end of the day. The reduced cost of labor means a great thing in terms of reducing the production costs. This also reduced the margin of error significantly in that humans are more prone to making errors than programmable machines.

自動スクリュー送りシステム can complete tasks at a very fast rate. The speed of operations within the company is therefore improved and made better. The machines can feed and fasten so many screws within a minute, which is a great thing for production.

The machine saves energy and time that humans would have otherwise used during the production process. Things are done very fast by the assembly automation screw feeders, and they do it without any time-outs, idle time, or coffee breaks.

Modern screw feeders can deal with small items such as screws, rivets, and nails. This means that the orientation and speed of every screw can be controlled. The main benefit of fast devices is that so many screws in their hundreds can be handled at a time.

Many industries benefit greatly from the use of machines. The industries include those that have to assemble many parts at the same time, those that deal with equipment, and component manufacturers.

自動スクリューフィーダーマシン

多くの場合, 自動送りドライバーシステム are used in processes that need to be repeated over and over again to be completed at any time.

の 2021, these machines are mainly used in the aerospace industry, the medical equipment industry, and consumer electronics industries. Having the machines at hand makes things easier and reduces the cost of production. また, these are industries where precision and special care are needed during production, installation, or assembly.