Os robôs parecem estar assumindo o controle das indústrias do futuro, e a área de aparafusamento não é exceção. Embora seja um processo que pode parecer muito simples, é um processo vital quando se trata de corrigir qualquer resposta, cartão eletrônico ou composto entre si.

Tal procedimento implica o fato de contratar pessoal especializado na área, que se encarregará de classificar o material destinado ao procedimento, encomendá-lo, and then carrying out the screwing process. Although this technique may seem economical at first, in the long run, the use of a lot of personnel in an area, it becomes a liability for the company: It dramatically increases production costs.

Portanto, several industries have sought solutions for the management of this basic process, and the future lies in the use of robots to replace personnel: A production line for counting, sorting, screwing and constant fixing.

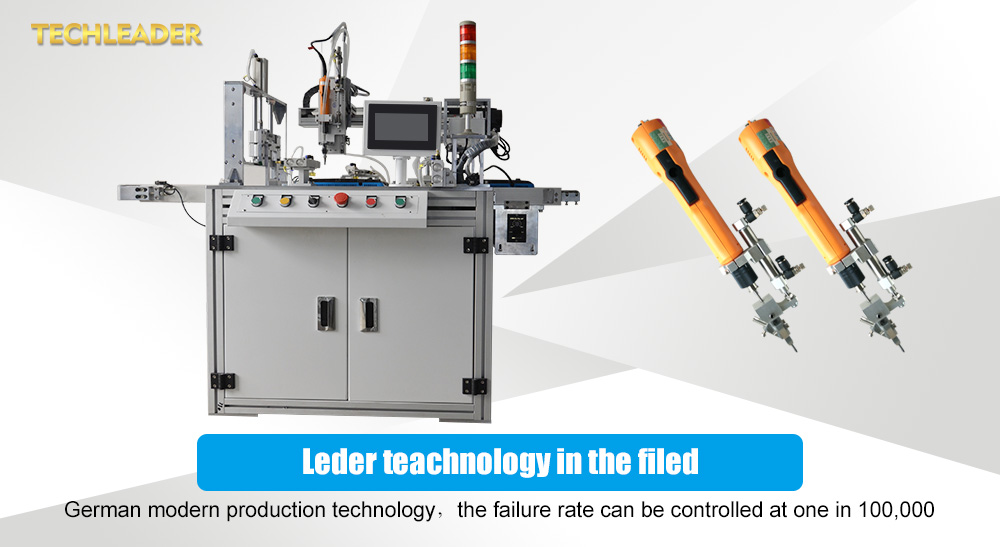

máquina para apertar parafusos automática

O que é a máquina alimentadora automática de parafuso?

Máquina de alimentação automática de parafuso is an assembly equipment manufactured for the task of supplying screws and screws in the field of automation, montagem de componentes, placas de circuito eletrônico, maquinaria, telefones inteligentes, eletricidade telefones sem fio, computadores, telas de navegação, caixas de som, máquinas fotográficas, pequenos dispositivos, toys … The machine has the function of quickly and accurately aligning screws. The machine can be used to classify and supply screws for assembly for different types of screw heads …and so on.

Automatic screw feeder machine function

This machine is the first but not least of the production line. O máquina alimentadora de rosca automática is initially responsible for counting the screws provided for each function. Nesse caminho, the quantity of raw material (screws) used in each base plate is assured, and no material is wasted in any way.

In addition to counting, the machine has the ability to receive the screws and gradually place them in a row to be used on the production line. This machine can be graduated to determine the speed of screw delivery.

By using said machine, the loss of raw material in screws is greatly reduced. The machine supplies exactly those that will be used for each plate and keeps a count of them. Nesse caminho, there is material to continue with the work.

In addition, it greatly facilitates the work of the máquina de travamento de parafuso automática, which will only have to remove the screw from the production line by means of a magnetized tip and will be ready to screw.

Function of the automatic screw locking machine in the automatic production line

This is the final part of the assembly machine. Being a robot, it has a screwdriver with a magnetized tip, which will allow you to remove the screw from the automatic screw feeder machine and through a previously given programming, it will seek to place it in the exact positions that were given and with the pressure level suitable.

This part supplies the necessary personnel for screwing. The staff will only seek to place the plates to be screwed and the machine will keep its work constant while placing and removing plates. Com isso, you have a fully automated production system, aimed at increasing production in large quantities. In addition, taking into account that it is an investment in a strong asset, it ends up being an investment in not so long term.

Studies indicate that the return on investment is from 6 months to 1 ano, and then the machine will be maintained with much longer life. A true marvel for technology in the bolting area.

Para saber mais sobre máquina alimentadora de rosca automática,you can pay a visit to para parafusos M1.0 – M4.0 todos podem ser aplicados://www.automatedfl.com