Роботы, кажется, берут под контроль отрасли будущего, и область завинчивания не является исключением. Хотя это процесс, который может показаться очень простым, это жизненно важный процесс, когда речь идет об исправлении любого ответа, электронная карта или соединение друг с другом.

Указанная процедура влечет за собой факт найма специализированного персонала в данной области., кто будет отвечать за классификацию материала, предназначенного для процедуры, заказываю это, and then carrying out the screwing process. Although this technique may seem economical at first, in the long run, the use of a lot of personnel in an area, it becomes a liability for the company: It dramatically increases production costs.

Следовательно, several industries have sought solutions for the management of this basic process, and the future lies in the use of robots to replace personnel: A production line for counting, sorting, screwing and constant fixing.

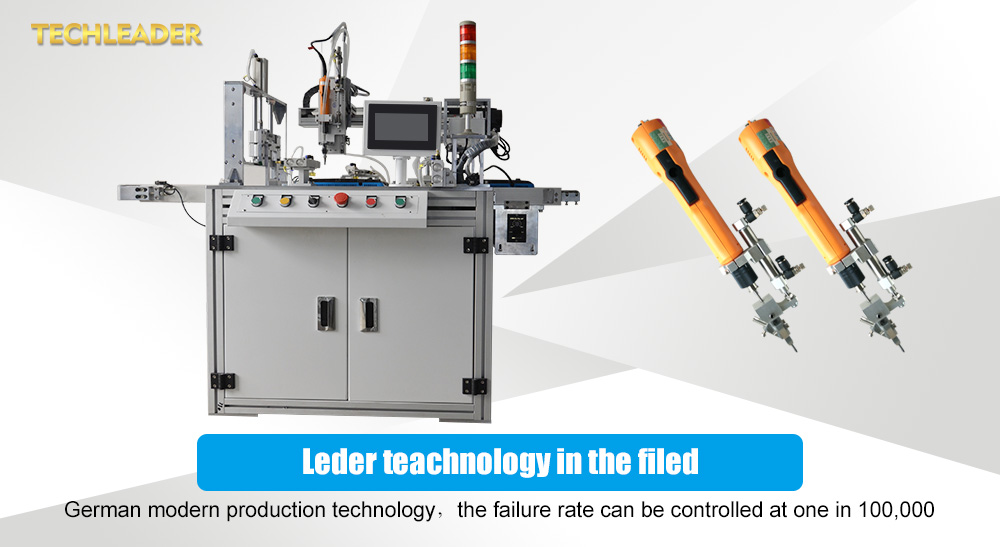

автомат для затяжки винтов

Что такое автоматический шнековый питатель?

Автоматический шнековый питатель это сборочное оборудование, предназначенное для подачи винтов и винтов в области автоматизации., сборка компонентов, электронные платы, машины, смартфоны, электричество Беспроводные телефоны, компьютеры, экраны навигации, звуковые коробки, камеры, маленькие устройства, toys … The machine has the function of quickly and accurately aligning screws. The machine can be used to classify and supply screws for assembly for different types of screw heads …and so on.

Automatic screw feeder machine function

This machine is the first but not least of the production line. В автоматический шнековый питатель is initially responsible for counting the screws provided for each function. В этом случае, the quantity of raw material (винты) used in each base plate is assured, and no material is wasted in any way.

In addition to counting, the machine has the ability to receive the screws and gradually place them in a row to be used on the production line. This machine can be graduated to determine the speed of screw delivery.

By using said machine, the loss of raw material in screws is greatly reduced. The machine supplies exactly those that will be used for each plate and keeps a count of them. В этом случае, there is material to continue with the work.

Кроме того, it greatly facilitates the work of the автомат для запирания винтов, which will only have to remove the screw from the production line by means of a magnetized tip and will be ready to screw.

Function of the automatic screw locking machine in the automatic production line

This is the final part of the assembly machine. Being a robot, it has a screwdriver with a magnetized tip, which will allow you to remove the screw from the automatic screw feeder machine and through a previously given programming, it will seek to place it in the exact positions that were given and with the pressure level suitable.

This part supplies the necessary personnel for screwing. The staff will only seek to place the plates to be screwed and the machine will keep its work constant while placing and removing plates. С этим, you have a fully automated production system, aimed at increasing production in large quantities. Кроме того, taking into account that it is an investment in a strong asset, it ends up being an investment in not so long term.

Studies indicate that the return on investment is from 6 months to 1 год, and then the machine will be maintained with much longer life. A true marvel for technology in the bolting area.

это увеличение, как правило, достигается за счет увеличения скорости вращения винтов. автоматический шнековый питатель,вы можете нанести визит https://www.automatedfl.com