로봇이 미래 산업을 장악하는 것 같습니다., 나사를 조이는 부분도 예외는 아닙니다. 아주 간단해 보이는 과정이지만, 모든 응답을 수정하는 데 있어 중요한 과정입니다., 전자카드나 복합카드를 서로.

해당 절차에는 해당 지역의 전문 인력을 고용한다는 사실이 수반됩니다., 절차에 필요한 자료 분류를 담당할 사람, 주문하다, and then carrying out the screwing process. Although this technique may seem economical at first, in the long run, the use of a lot of personnel in an area, it becomes a liability for the company: It dramatically increases production costs.

그러므로, several industries have sought solutions for the management of this basic process, and the future lies in the use of robots to replace personnel: A production line for counting, sorting, screwing and constant fixing.

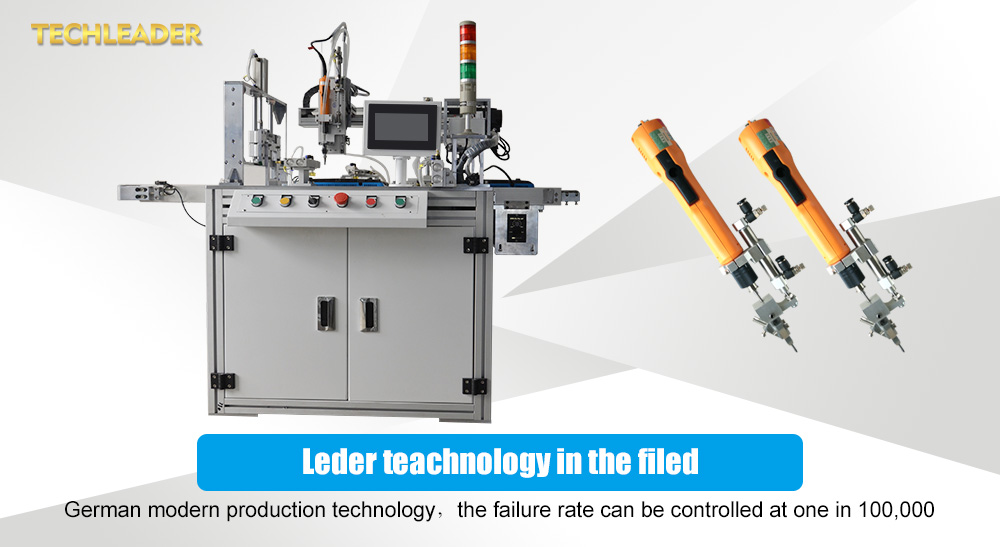

자동 나사 조임 기계

자동 스크류 피더 기계는 무엇입니까?

자동 스크류 피더 기계 자동화 분야의 나사 및 나사 공급을 목적으로 제작된 조립 장비입니다., 부품 조립, 전자 회로 기판, 기계, 스마트 폰, 전기 무선 전화, 컴퓨터, 탐색 화면, 사운드 박스, 카메라, 작은 장치, toys … The machine has the function of quickly and accurately aligning screws. The machine can be used to classify and supply screws for assembly for different types of screw heads …and so on.

Automatic screw feeder machine function

This machine is the first but not least of the production line. 그만큼 자동 스크류 피더 기계 is initially responsible for counting the screws provided for each function. 이런 식으로, the quantity of raw material (screws) used in each base plate is assured, and no material is wasted in any way.

In addition to counting, the machine has the ability to receive the screws and gradually place them in a row to be used on the production line. This machine can be graduated to determine the speed of screw delivery.

By using said machine, the loss of raw material in screws is greatly reduced. The machine supplies exactly those that will be used for each plate and keeps a count of them. 이런 식으로, there is material to continue with the work.

In addition, it greatly facilitates the work of the 자동 나사 잠금 기계, which will only have to remove the screw from the production line by means of a magnetized tip and will be ready to screw.

Function of the automatic screw locking machine in the automatic production line

This is the final part of the assembly machine. Being a robot, it has a screwdriver with a magnetized tip, which will allow you to remove the screw from the automatic screw feeder machine and through a previously given programming, it will seek to place it in the exact positions that were given and with the pressure level suitable.

This part supplies the necessary personnel for screwing. The staff will only seek to place the plates to be screwed and the machine will keep its work constant while placing and removing plates. 이것으로, you have a fully automated production system, aimed at increasing production in large quantities. In addition, taking into account that it is an investment in a strong asset, it ends up being an investment in not so long term.

Studies indicate that the return on investment is from 6 months to 1 년, and then the machine will be maintained with much longer life. A true marvel for technology in the bolting area.

에 대해 더 알아보기 자동 스크류 피더 기계,당신은 방문을 지불 할 수 있습니다 https://www.automatedfl.com