How Have Screw Fastening Tools Improved Accuracy Of Manufacturing Fully Automated Assembly Line

At first, most of the things were made manually or completely handmade; however, with the advancement in sizes and quantity, machines have started to prevail in industrial work. Things like heavy equipment and many other large materials, manufacturing get easier with hi-tech machines.

One of the most important aspects considered by the manufacturers is reliability, safety, and good quality output. To make sure that these conditions are fulfilled, manufacturers have started to use accurate tools to make heavy equipment. To achieve these safety and quality standards, most manufacturers are switching to different kinds of tools.

Not only do these tools provide good safety and quality to the product, but they also provide high accuracy in the manufacturing of heavy equipment. Since most of the customers have this demand to be served with safe products, it gets necessary for the manufacturers to reassure the quality and accuracy.

When it comes to the manufacturers using tools, there are a wide variety of available tools. The range of tools starts from basic tightening tools to hi-tech assembly. Below we have mentioned some of the best tightening tools that improve accuracy in the manufacturing of products.

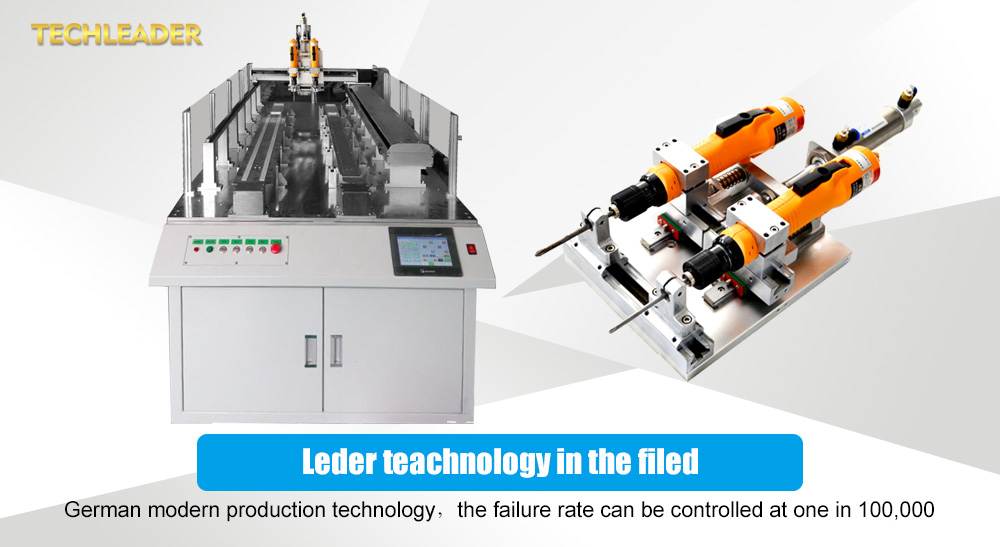

automatic screw locking machine manufacturer in china

Impact Wrenches and Drill Drivers:

• An impact wrench is one of the fastest types of tool which can fasten and tighten a bolt very efficiently. This type of range is beneficial for loosening and removing stubborn bolts. Since removing bolts is usually hard, impact wrenches are more precise and accurate for removing heavy equipment bolts during any repair and maintenance.

• You may also need to use a clicker torque wrench to measure the torque of the impact wrench that is achieved during the passion of the bolt.

• The drill driver Mode of this tool allows different speeds with different power. This feature also provides more accuracy while working with heavy equipment.

Pneumatic fastening tools:

• Compared to the impact wrench, pneumatic fastening tools are more powerful when used on any screw and bolt. This type of fastening tool is usually used for applications that require high torque because there can be variations in pressure due to impurities in air delivery.

• Pneumatic fashioning tools are commonly used on larger-sized boards that are fixed on heavy equipment. These fastening tools have a lot of pressure, which is why the supervisor or the operator of this machine also needs to use a reaction bar.

• However, pneumatic tools can only be used to fasten large size bolts only with a single speed. They can not be used with variable speed.

Direct current fastening tools:

• All of these smart fastening tools have a tool controller which powers them. This tool controller transfers current through this power cord supplier. These DC tools are very efficient and provide the ultimate accuracy and traceability while working on heavy equipment.

• However, since they are connected with a power supply cord, they have a typically slow speed of fastening in bolts and screws.

• Moreover, these tools are comparatively costly as compared to other fastening tools. It is quite difficult to operate DC fastening tools. That is why they require experts and trained technicians to operate this tool.

Finding torque and accuracy is essential:

• Manufacturers have found out that it is important to find out the torque and accuracy of running these equipment types. It is also stated that those equipment that has high torque are comparatively more traceable and accurate.

• Most of these operators of this machine tend to program it at variable speeds throughout the process. It is one of the advanced settings that these operators implement, and it is also very simple to implement it.

• This advanced setting also alleviates those bolts that are over-tightening and gives off better accuracy in this work.

• Moreover, this machine produces very little noise and can be more feasible for a heavy working environment.

Assembly arms better prevent errors:

• The torque arms present in these tools are provided for a better counterbalance of the tool’s weight. Moreover, they also absorb the torque reaction. The smallest size of the Assembly arm can absorb up to 10 feet-lb of torque. The range of its reach is about 8-28 inches.

• However, the larger one can observe up to 30 feet-lb of torque; moreover, the reach of the larger assembly army is 18 to 37 inches.

• These torque reaction control arms consist of either horizontal or vertical linear slides for functioning. This makes sure that the operator installs nut screws, bolts, and rivets properly with perfect perpendicularity.

• These assembly arms are available either with the machine or separately.

Tool tracking technology:

• The best way for tool tracking is to install a high-resolution camera with the tool. These products contain a high-resolution camera with high-speed functioning. This technology has been used to achieve ultimate quality and best traceability with assembly verification as well.

Cordless riveters:

• These tools are used for telling the operator if the set is bad or good. It can record the data and feature the barcode reader so that the user or operator can change or switch between projects.

automatic feed screwdriver system manufacturer

Preset-torque screwdrivers:

• The operators usually use an analyzer to preset the torque value required while working with the tool. This tool cannot be adjusted with an external scale, and you must preset it using the analyzer only. It has an indication in which the radial ball clutch will slip-free as soon as the required preset torque is attained.

• It is mostly used in situations when there is only one torque setting required. However, it is very easy to preset the torque, and the screwdriver is flexible enough to change torque quickly.

• There are different colored end caps available, for example, in black, red, green, and blue color, which can be used as color-coding identification of the preset torque value that you have set.

Summing up, these are the few things that help improve the accuracy of the fastening tools.