Handheld Screw Feeders- A Substitute For Automatic Screw Feeding Systems?

The popularity of automatic screw feeders has been increasing over the years. Their importance in the production process cannot be undenied. However, not all companies can or will need an auto screw feeder for their purpose. Such companies go for a handheld screw feeder.

Given that the two pieces of equipment require different levels of human interaction, the contrast between the various features and characteristics of the handheld and auto screw feeders will bring out each machine’s advantages. This may also help companies make up their minds about choosing the machine to buy while changing the production scale.

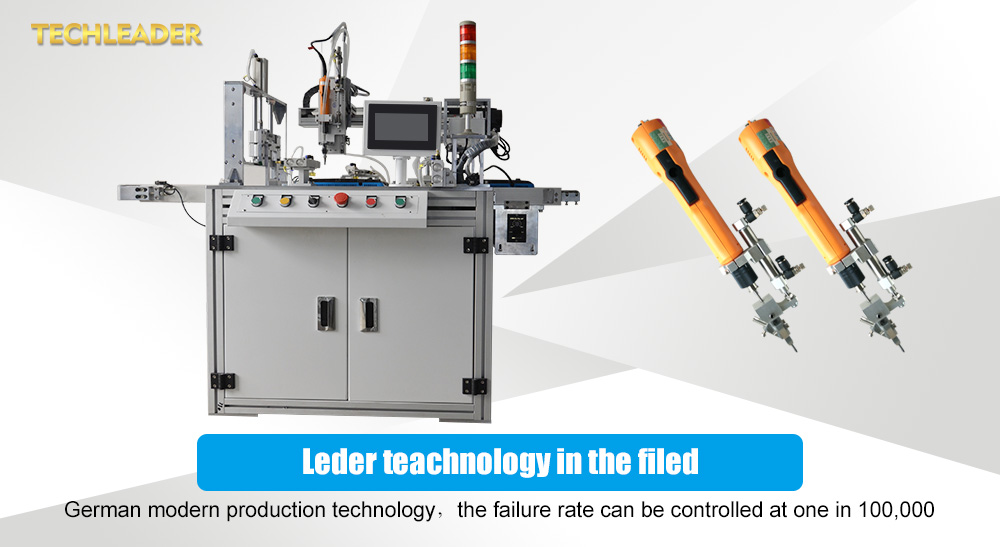

automatic screw tightening machine

Auto Screw Feeders

Auto screw feeders automatically put and fasten screws, replacing the need for human hands and a reduction in human-induced errors. They are used in the production processes that revolve around screws, like the electronic, automobile, aviation and packaging. These feeders are known for their reliability and productivity and help cut down costs.

Auto Screw Feeders mainly come in two types: fully automatic screw feeders and handheld screw feeders.

Fully Automatic Screw Feeders

The fully automatic screw feeders can be extended to existing robotic mechanisms or directly included in the production process. These screw feeders are divided into three-coordinate fully automatic screw feeders and multi-axis fully automatic screw feeders.

The multi-axis fully automatic screw feeders have different stroke movements in the Y and Z-axes, whose orders can be made according to the client’s requirements. The screws are fed either through a pneumatic or suction method, determined by the screw’s specifications. For meeting the needs, a pneumatic approach is usually adopted.

The three-coordinate fully automatic screw feeders have manual, pneumatic and suction feeding methods. The choice of method is decided by the type of screw used. However, the machine is most likely to be used with the pneumatic feeding method.

Handheld automatic screw Feeders

A handheld automatic screw feeder allows one hand to be left free. The feeder has to be placed in the hole where the screw has to be fitted, and the feeder will shoot a screw into the hole. This is the process that is to be repeated multiple times.

A handheld automatic screw feeder transfers and locks screws continuously. The feeder can feed up to 60 screws per minute, which saves time labor costs and increases productivity and efficiency. Once the screw is locked, the feeder shoots a screw so there is no need to move, fetch or aim the screws.

There will be no need for repeated feeding as one has to only lock the screw feeder with a gentle press. This process is also easy and highly convenient. The handheld automatic screw feeder can work with the same torque adjustment with the wind batches and the original screwdriver, cutting down production costs.

The feeder’s electric batch is portable, which reduces the effort of workers using it. It can be operated as a separate machine or as an extension of the production line, thus quickly increasing the quality of the screw fastening and the production efficiency. Like the fully auto screw feeder, the handheld auto screw feeder has applications in multiple industries like electronics, aviation and automobiles.

Automatic Screw Feeding Machine

Both these machines have their distinct features and advantages. However, it cannot be ascertained whether one is better than the other. Each is better in particular ways and particular circumstances, and a good company will make the most of them both.For more about automatic screw feeding systems,you can pay a visit to CalvinDude at https://www.calvindude.com/ for more info.