New trends in the automatic screwing machine world

Times have changed, and we can no longer ignore the benefits that are associated with automation, many manufacturers are now discovering how much better their processes can become when the best techniques are applied. It is important to think of the best way to improve production and satisfy the available market regardless of its industry.

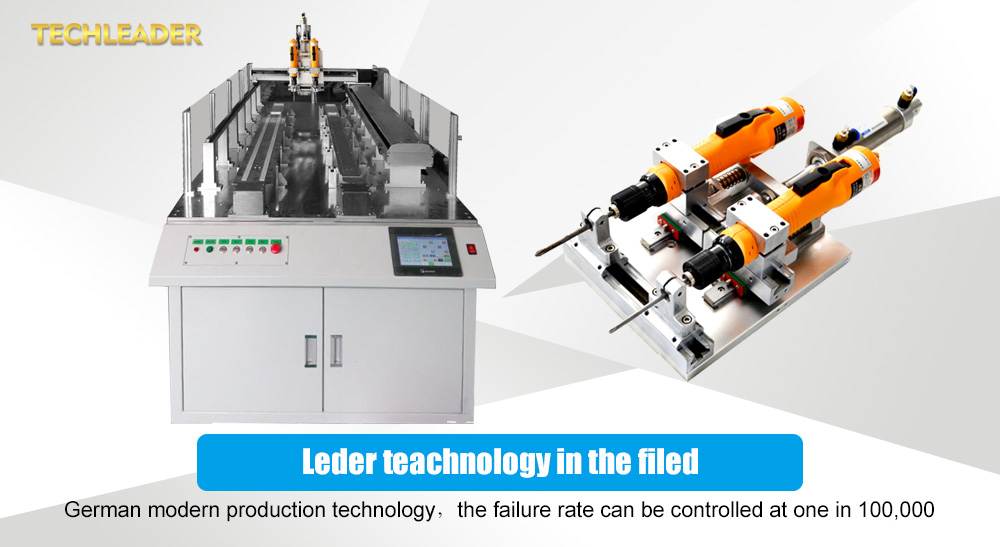

One of the areas that most manufacturers are targeting is the automatic screw driving systems. This is an important category that you should consider investing in, especially if you want to boost accuracy, quality, and productivity. You need things to be done fast, safely, and efficiently. An automatic screw driving machine can help you achieve all these and so much more.

China automatic feed screwdriver system manufacturer

Reducing downtime

Today, most automatic screw dispenser manufacturers are devising ways that enhance reliability and speed. These new things help reduce downtime and improve the assembly process. By including machines to eliminate waste and improve the process. You will not need so many operators handling the fasteners.

Data-driven drivers

In today’s world, the demand for tools that offer quality assistance, speed, reliability, and an easy setup is rising. This is why we see so many systems using different screw driving controllers and systems to offer the best torque control. This also ensures traceability and joint integrity.

Double workstation and double head screwing machines

Modern automatic screwing machines assist engineers in coming up with products that can be assembled easily and with a good design. This is achieved by reducing the fastener counts and relocating fasteners to make access better. This is done by the automatic analysis and capture of data. Today, machines can easily predict failures and prevent them from happening. This adds to productivity and inefficiencies. Data collection is a great trend today. There is the use of track and trace tech providing a very detailed record of the entire process.

Flexible fastening

To make things better, engineers are working at adapting one machine to handle as many products as possible regardless of where screws are located. This is the reason why work cells are being integrated to the automatic screw driving systems. Such cells do not need much operator interaction. When manual iterations or changes are made on products, it means that the same equipment can be used to assemble the new versions, reducing the maximum consumption of power.

automatic feed screwdriver system manufacturer

Feeding time

Manual installation of a screw requires an assembler to retrieve screws from different bins, ensure they are aligned with the holes and then fastened. However, the automatic screw-driving machines make things easier. The operator only needs to have the driver set over the area that needs to be fastened. The auto-feed machines offer great control during assembly. It is easy to control the screw driving process in terms of fastening speed, tightening direction, torque, and rotation angle.

Automatic screw feeder machines are ergonomically superior and efficient. They are faster compared to manual systems, and they reduce waste while improving quality. In many operations, the screw driving systems offer great solutions that ensure the assembly process is streamlined.