Special china automatic screw feeders features you could request from your supplier.

Automatic screw dispenser manufacturers always devise ways to make manufacturing processes and assembly plans as convenient as possible. This is why upgrades and updates are always being made on different machines to make them more efficient, diverse, and functional.

Different mechanisms inspire machine creation, and the best methods are always upgraded for an even better and modern experience. Automatic screw feeder machines need to be able to perform the tasks that they are meant to handle. It is important to buy a machine that is capable of handling your processes conveniently.

automatic screw driving machine

Some automatic screw feeder machines utilize horizontal feeders to reduce jamming risks. They are also created in a way that they can support different screw types created with different materials. The best machines also handle screws of different sizes. The most important thing that automatic screw dispenser manufacturers do is develop innovative technologies that make production lines more efficient and offer them customized solutions.

Some of the special features that a machine can have include:

1. Use of different types of screws

After evaluating your system, you can easily tell what you need. You will understand all the processes involved in the production and then concentrate on getting machines that can make them as fast and as efficient as possible.

This is a special feature you can ask your manufacturer of choice to include. When you get a jam-resistant feeder with the best renders, it can handle different types of screws. This is because such machines can be customized to handle different crafts, sizes, and screw shapes. An automatic screw dispenser manufacturer can guide you and custom make a machine to your specifications.

2. Production style compatibility

There are instances where different production styles are done in the same company. If this is your case, then your automatic screw feeder can be created so that it can be easily tuned for manual and automatic use with different screws. The models can be equipped with specific counters, so a specific number of screws are dispensed. Machines can be tailored to match the needs of your company.

3. Different model sizes

It helps to choose an automatic screw fastening machine available for different uses. Different sizes can handle different capacities. You notice that some of the models can be enhanced even further with more storage cases.

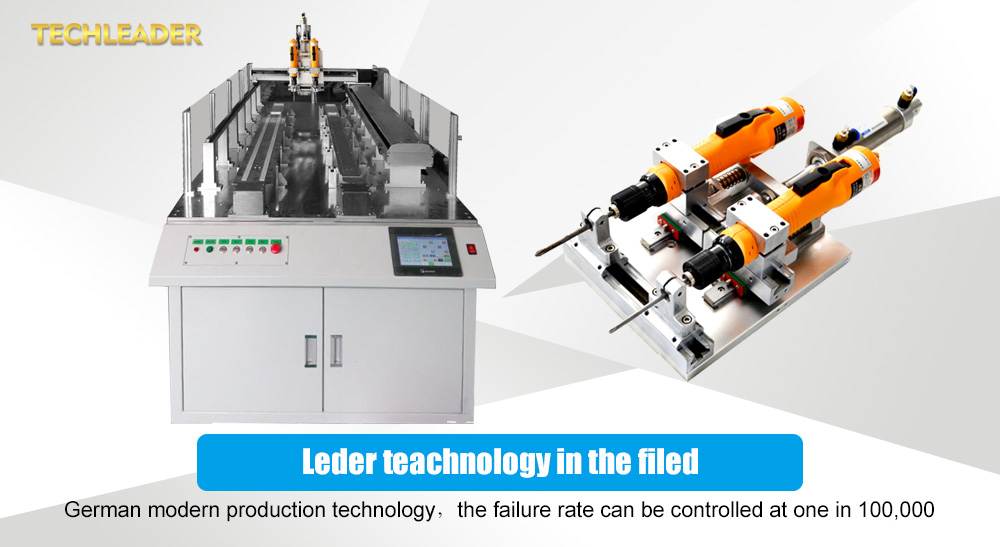

4. Specific technology

Some people are very specific about the technology they want to apply in their production plants. These are usually technologies that have proved to be of high quality in terms of sound management and materials used. You can also pick a simple but functional design machine and a structure that can be easily repaired.

automatic feed screwdriver system manufacturer

5. Version updates

This is the last special quality you can look out for when choosing an automatic screw tightening machine. You should pick a company that offers version updates which means functionality improvements and durability.

Software updates, upgrades, and other additions are always meant to offer the company some form of support in a great way.