What Is The Automated Screw Feeder Machine

An electric or automatic screw feeding machine is a very useful device with numerous applications. It effectively sorts and supplies the screws in convenient rows to pick and tighten at a much faster speed. While working on a larger scale, it shaves off valuable seconds and increases your output efficiency greatly. This remarkable automatic screw feeder system is mostly used in automatic assembly mechanisms as well as for DIY purposes. This particular feeder machine proves very helpful in the production of various vehicle or computer components, display screens, circuit boards, different types of motors, cellular phones, printers and batteries.

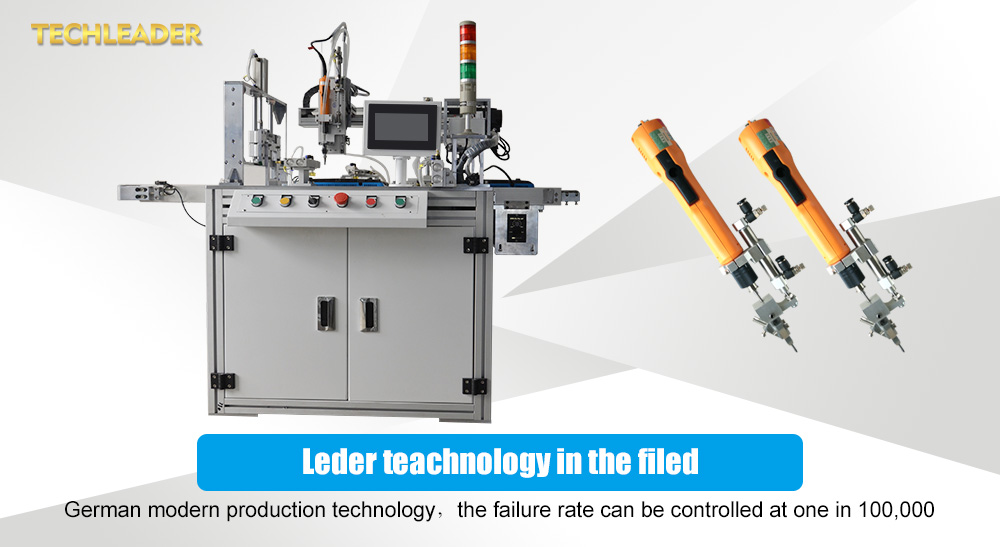

automatic screw tightening machine

How A Screw Feeder Machine Works

There are many sizes of screws used in the assembly of machines. Dealing with the smaller ones can be quite a challenge. Every time you have to straighten and pick one from the unsorted pile and then put it in place and tighten it. It can become hectic if you have to repeat this process a hundred. The automatic screw feeder machine manufacturers have provided the users with ultimate convenience. This machine sorts the screws and supplies them one by one to be tightened. It is efficient and requires no effort in sorting and arranging the screws by hand.

Types of Screw Feeders

There are two types of screw feeders. Both offer individual benefits to the user.

Handheld Automated Screw Feeder

While putting in screws in any type of machine assembly, both hands had to be engaged. You have to pick and position a screw with one hand, while the other hand has to operate a manual screwdriver or an electric one for locking it in. Then you have to repeat the same process for the next screw and the next one after it. With an automatic handheld screw feeder, the screws are transferred directly for locking one after the other. During this process, one hand is completely free to utilize as needed.

A handheld automated screw feeder offers the following benefits:

1. There is no need to put the screws one by one into position. The screws are easily supplied via the handheld device and locked in without any delay. This improves work efficiency as the device helps to lock in 40 to 60 screws per minute.

2. When one screw locks in its place, another one is supplied through the nozzle right away. This saves time with every screw placement and locking. For large-scale assemblies, it could mean saving many work hours.

3. It is very easy and convenient to work with. The user only needs to aim the nozzle in position at the screw hole and then press lightly to lock in the screw.

4. The device can be utilized with an original screwdriver and wind batches where the same adjustment of torque is used to save purchase costs.

5. It is a portable device with an electric batch kit. It is very helpful in reducing worker fatigue.

6. It can be retrofitted for singular usage or within a specific assembly line. With assembly configuration, the device can be used to move up or down a particular product until the job is done effectively and efficiently.

7. It is the best option for the automatic assembly line production of electronics. The assemblies of sensitive products like mobile phones, small motors, hard drives, any communication equipment can be done to perfection with it. It is also used in toy manufacturing and other plastic products.

Fully Automated Screw Feeder

A completely automatic screw feeder machine is ideal in all aspects. It offers more usability and added benefits than a handheld device. It also improves the functionality range to include features like a robot arm, a workbench, automatic control etc. This makes the automated screw feeder a highly beneficial product. It sorts, arranges and supplies screws in a rapid progression for lightning-fast locking of the screws without a miss.

Benefits of using an automated screw feeder machine:

1. It is perfect for high-end product manufacturing and critically refined finishing. It offers precision and saves time and manual effort.

2. It can be implemented for unsupervised usage which also saves labor expense while improving work output many folds.

3. It offers simplicity for complex assemblies with very low power consumption.

4. It can be fitted with flexible layout arrangements to work with a multitude of product specificities.

A completely automated screw feeder is further divided into two types.

Three-coordinate automated screw feeder

This type of completely automated screw feeder moves in three coordinates. It has an X, Y axis and several Z-axis movement plains for which the device can be customized as per the user requirement. In layman’s terms, the device has two fixed axis and one adjustable axis. It facilitates Suction or Pneumatic methods of screw feeding. The feeding method can be adjusted but the screw feeding requirements. The pneumatic method of feeding is generally adopted by the users mainly for the convenience it offers.

The multi-axis completely automated screw feeder

A multi-axis fully automated screw feeder is a specialized lock-payment mechanism. It is customized for a fixed purpose and cannot be altered to work on multiple products. It gives multiple options for screw feeding methods i.e. manual feeding, suction feeding or pneumatic feeding. These methods can be chosen as per the screw specification requirement. The preferred method for a multi-axis automatic screwdriver is the pneumatic feeding method.

For any type of assembly or production facility, the automatic screw feeder system can be customized to fit the specific set of requirements. The handheld device is perfect for personalized usage as well as assembly line installation. This remarkably automatic screw feeder machine manufacturers offer several customizations of this device for specified usage. It is ideal for the large-scale production of a single product.

automatic screw fastening system manufacturer

For DIY enthusiasts, it is perfect to avoid fatigue and maximize work output. For industrial usage, it gets the job done with minimal supervision along with reduced electricity and labor costs. This device is affordable with an extended lifetime. With careful usage and periodic maintenance, this device can benefit an array of users for a long time.

For more about automatic screw feeder machine,you can pay a visit to china automatic screw feeder machine manufacturer Huizhou Shengyang at https://www.automatedfl.com/ for more info.