Automatic screw driving machines and the different types in the market

An automatic screw machine is one of the greatest inventions, especially in the production and assembly industry. This lathe is used for shaping arterials into different designed components. In most cases, the machines work by simple rotation of workpieces at high speeds. This allows different tools to work in the workpiece.

There are different screw machines available. The way they work is based on a single fundamental principle. Screw machine, when used as a term, can be somewhat misleading. This is because machines are often used in the production of different types of components. They are not restricted to screw driving only.

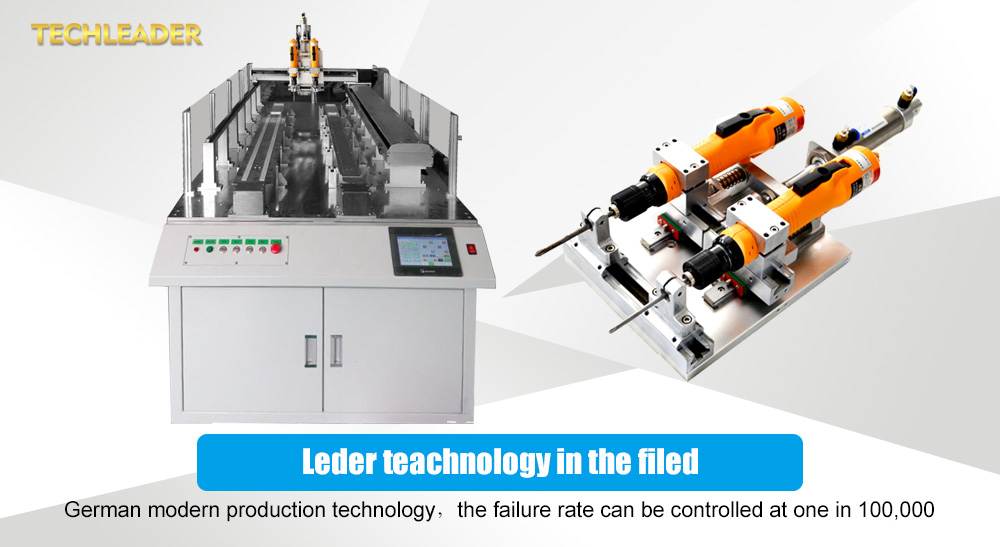

china automatic screw feeder machine manufacturers

The types of screw machines

Screw driving machines have been evolving over time. It has been a journey getting to the modern automatic screw driving machines. The automatic screw dispenser manufacturers have been working hard to produce the best over the years.

Turret lathes

These were the first tools to be used as screw driving machines back in the 1840s. They were used for pistols and percussion licks. They consist of vertical and horizontal rotating turrets fitted with various cutting tools that move towards a rotating workpiece. When an operation is complete, the turret slides, and then another workpiece is placed.

After all the tools have been shaped, the product is released, and the cycle continues. The manual versions are no longer used. We now have the automatic screwdriver systems replacing them.

Cam-operated/lathe screw machines

These machines are automated mechanically using disc cams. They became popular in the 1860s where the cams transformed the rotary movements into linear movements. The linear motion advanced cutting tools into rotating workpieces. This was the very first automated screw machine. These machines have been replaced by the CNC operate machines even though fabrication workshops still use them.

CNC turning centers/ CNC lathes

In this case, cutting tools are computer-controlled. The machines are also a type of modern automatic screw driving machines. The machines do not rely on cams for rotation. The movement is usually electronically controlled using programmable user input. They became popular in the 50s and are today amongst the most popular machines superseding the cam-operated ones. They are enhanced in accuracy and precision. The changeover rate is also fast, making them the ideal automated screw fastening machines.

Swiss screw machines

These are also a type of automatic screw feeder machines that have guide brushing and sliding headstock. The headstock secures the workpiece and collect. This clamps the piece rotating it using a spindle. The tools then move in and out, trimming the bar’s diameter and shaping the cross-section overall. The headstock then moves backward and forward to come up with the right length. These machines became automated by the inclusion of rotating cams. Later the CNC versions gained popularity. Presently, Swiss machines are amongst the most popular options in screw driving technology.

automatic feed screwdriver system manufacturer

Multi-spindle machines

In this case, the machines have multiple spindles to rotate hold and come up with different workpieces simultaneously. These machines are either CNC or cam operated. They are popular with fabrication facilities where repeatable accuracy and mass production is desired.