The beneficial side of the automatic feed screwdriver system

When it comes to the best production practices, automation is an important part of it all. There are many benefits of finding the best automatic feed screwdriver system to help with your production. For manufacturers, units may be used for screw delivery in a fast manner.

One of the hardest things to do is decide the best machine to invest in. However, there are many benefits of getting an assembly automation screw feeder to aid with your production needs.

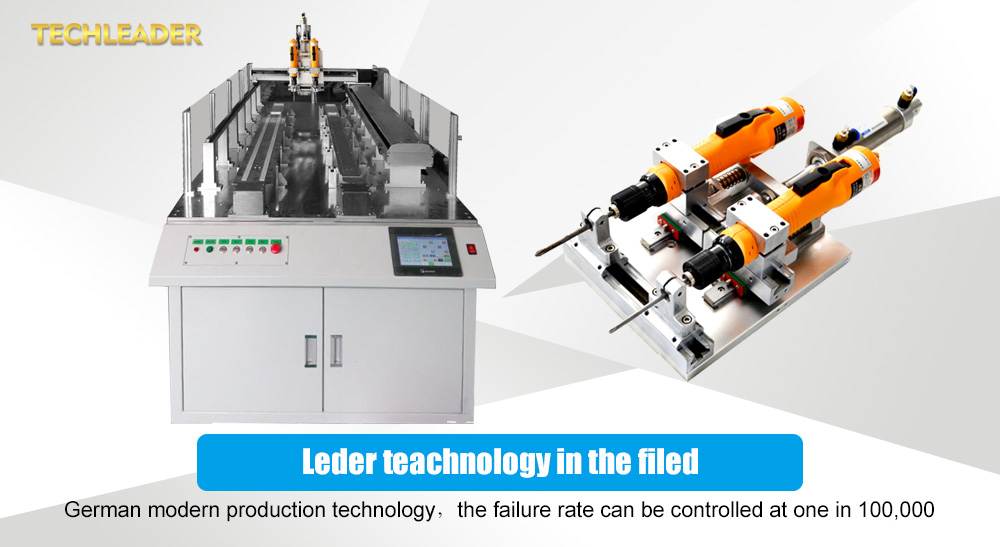

automatic feed screwdriver system manufacturer

The beneficial side of these screwdriver systems include:

Flexibility and efficiency

In many cases, a business needs to use different screw types. There are cases where very distinct measurements are needed as well. One of the main benefits of using these kinds of dispensers is that they are available in parts that can be interchanged. This means that different screw types may be used with slight or no adjustments.

There are some processes that need precision and detail to add onto accuracy. If the wrong screws are used, things may not work out well for your device or product.

Automatic feed screwdrivers feed the right kind of screw. This means that the wrong screws will never be fed. Most of the machines come with quality controllers, ensuring that the devices are assembled well, and no additional work will be needed.

Screw movement

When the screw feeding process is quickened, the entire tightening process becomes faster. Using a two-lift portion is adequate to bring the right number of screws to the presenter. This means better performance. The screw usually goes to the guide rail at the top, and then it is positioned.

There are screw presenters that can combine feeder system movement in the best way possible, making it possible to complete the fastening process faster than would have been possible manually.

Self-sufficiency

Most of the assembly automation screw feeders are self-sufficient. With a micro switch and a light barrier, the screw cup can be managed by the arrangement controller. This makes it easy to control the auto screw feeding system safely.

Easy to use

One thing to note about the auto screw feeding systems is how flexible they are. This makes it easy for them to meet different project needs. The assembly automation screw feeders can be configured when a new project comes up. Consumer electronics are popular today, and having the best dispenser makes it possible to meet brand requirements no matter how diverse they are.

Compact style

When a workspace is neat and organized, accidents rarely happen. When you are dealing with complex assignments, neatness is important, and it helps when you can have as much room as possible. Most of the automatic screw feeder machines have compact designs, making them a great fit for tight workspaces.

handheld automatic screw locking machine

There are different types of assembly automation screw feeders, and they come in all shapes and sizes. The most important thing is to make sure all processes and industry needs are understood clearly. This is the only way to get a machine that is cost-efficient and reliable for the tasks.